By Lisa Allen, Director of Regulatory Affairs, International Lead Association

As plans go it’s a good first step. But the steel and metals action plan published by the European Commission needs to go much further.

Europe needs a wide range of metals to support its ambitious plans for growth, for economic stability and for defence. And we want to produce as many of those metals in Europe as possible. That’s the political message we need to see coming from Brussels. Support for all the essential metals produced in the EU.

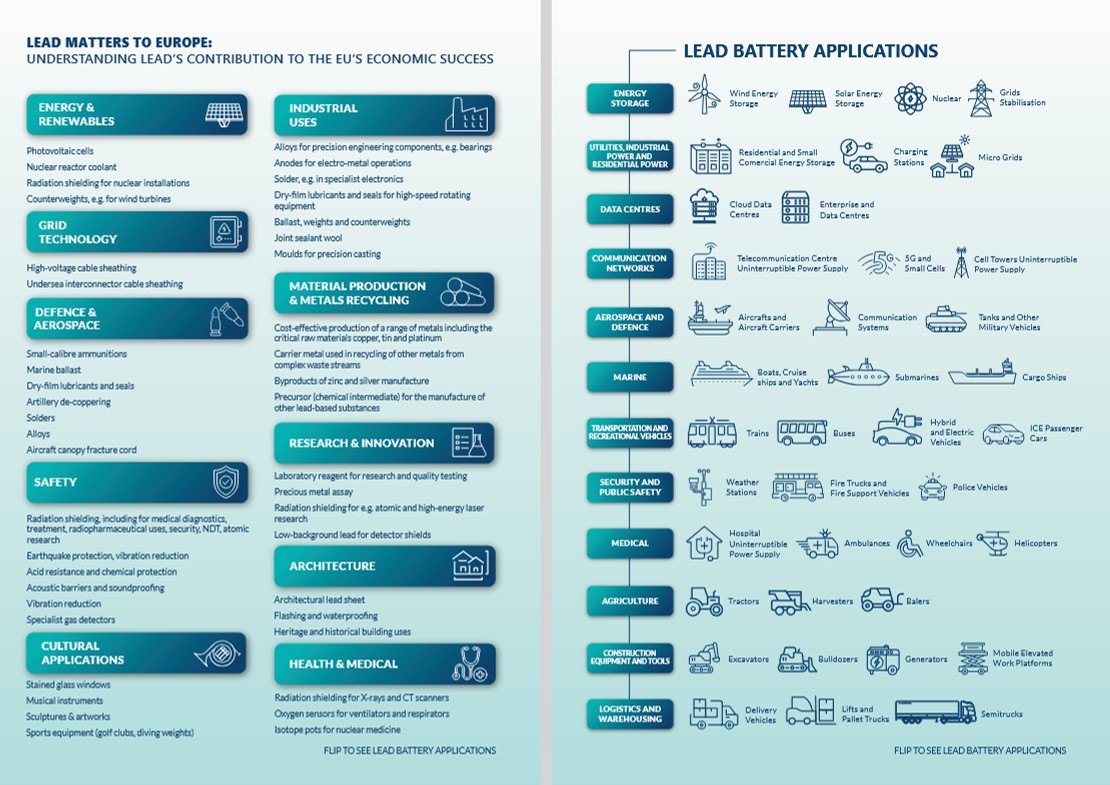

So far the plan is a missed opportunity to seize the moment. We need to see a much broader metals action plan that includes essential materials such as lead – already an example of how a closed loop recycling system should work. All the lead batteries recycled in Europe re-used to make new batteries, for everything from backing up hospitals and nuclear facilities to specialist batteries for armored vehicles and submarines.

All made in Europe and recycled in Europe. And we need to keep it that way.

The Commission states in the action plan that the metals sectors covered share common challenges for their competitiveness: “high energy costs, exposure to an unlevel playing field in international competition, decarbonisation investment needs and regulatory burden.”

We need to ensure that successful industries like the lead value chain, already complying with the most stringent regulatory regime in the world, are not disadvantaged globally. The European lead industry is circular, has a secure supply-chain, the lead value chain provides 30,000 direct jobs in the EU, and underpins sectors critical to the EU’s green transition. The transformation that the European lead industry has undergone could serve as a blueprint for enhancing the strategic autonomy, circularity, and sustainability of other sectors:

Lead is used in strategic applications: 85-90% of lead is used to make batteries that support the automotive industry, aerospace and defence, critical backup power for telecoms, data centres, hospitals, nuclear installations, and other critical infrastructure, and (renewables) energy storage.

Lead batteries are already circular: Lead batteries operate in a closed-loop system, with nearly 100% of used batteries collected and recycled. The average lead battery contains more than 80% recycled content, and over 95% of a used lead battery can be recycled to produce battery-grade materials.

The EU is self-sufficient in raw materials required for lead battery manufacturing: Lead is the EU’s most recycled metal and more than 75% of Europe’s lead already comes from recycled sources.

Lead is a carrier metal, enabling the efficient production and recycling of othermetals – including 6 Critical Raw Materials – many of which contribute to future breakthrough technologies for a more sustainable economy.

The Steel & Metals Action Plan is a good start but it needs to provide a more robust political signal to the entire European metals industry. With a regulatory framework on chemicals management, permitting, and recycling that provides the lead industry with the regulatory certainty it needs, we stand ready to continue our successful contribution to EU green competitiveness – now and in the future.